E-mail : huayun@bdhyjx.com

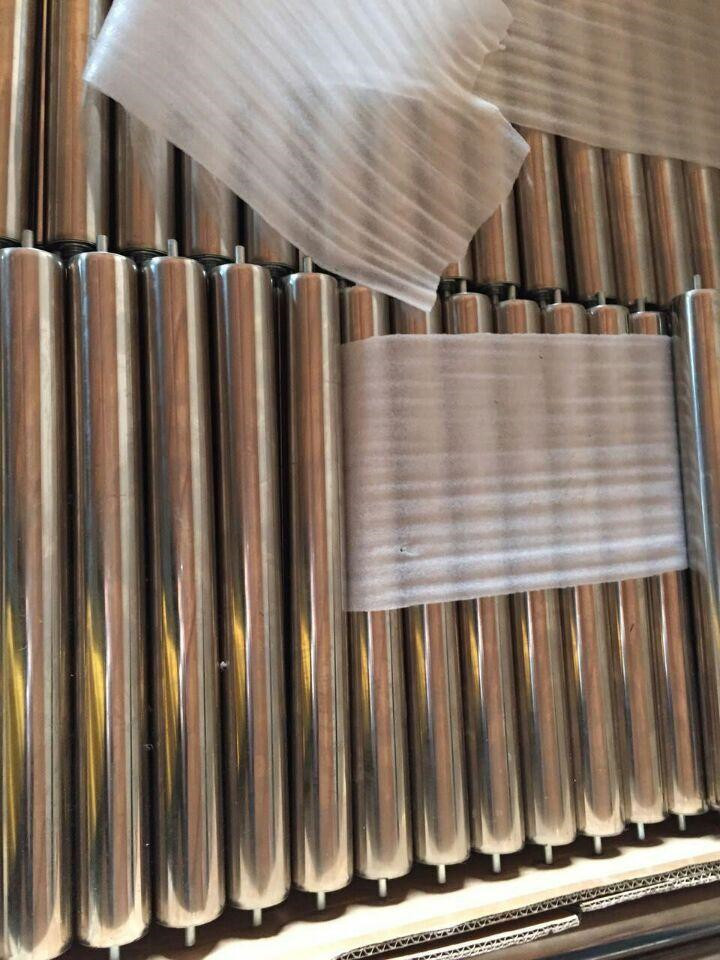

Gravity Roller

304 Stainless Steel Roller is a great way to load & unload lumber or ladders for your Roof Rack. This roller is a cost-effective way of getting your ladder on your roof racks without a full ladder system.

Corrosion-resistant stainless steel conveyor rollers can withstand frequent washdowns, high humidity, exposure to corrosive chemicals, and other harsh conditions that might corrode steel or aluminum rollers. They are suitable for conveying applications in facilities that process food, chemicals, or pharmaceuticals. The rollers contain standard ball bearings that roll smoothly at slow speeds and start rolling more easily than precision bearings. Conveyor rollers are used in roller conveyors and material transport stands to support and move bulky items. The rollers let loads roll from one place to another, reducing the effort it takes to move the loads. These rollers can be used to replace or upgrade the existing rollers on compatible conveyors or stands.

A gravity roller conveyor lets a product move on rollers using the force of gravity to move the load. Gravity conveyors are one of the simplest and affordable types of material handling systems. They work by allowing the product to roll along the upper surface. When mounted on a slight decline the parts begin moving across the rollers. They are great for warehouses, production facilities, or distribution centers.

Gravity Roller Conveyor. This is the most common type. It has no motors.

Gravity Conveyor Belt. Many people use this term for roller conveyors. But they have no belt.

Powered Roller Conveyor. These systems have rollers powered by a motor. There are two main styles, motor driven roller conveyors or chain driven live roller.

Belt-driven roller conveyor is another alternative where the rollers are driven by a belt. These types of conveyor are more common for curves.

Line-shaft roller conveyor. Another variation of a belt driven roller conveyor.

Heavy Duty Roller Conveyors. These generally refer to roller conveyors that have roller diameters of 2.5″, 3.5″ or larger. They are not very common as generally conveyors for heavy loads have motors.

Follow this simple process to help you choose the correct model conveyor:

Choose the width of the conveyor you need based on the product dimensions. Allow at least 1 inch on each side for clearance. Consider wider widths or side guides if the product can slide sideways.

Decide on the length of the roller table you need. Lengths of 5 or 10 feet can easily connect. Add curved sections to achieve the layout required.

Check the load rating table that shows the load capacity of each roller. Use light duty 1.5″ rollers for product loads under 100 pounds. Use medium duty 1.9″ rollers and frames for loads over 100 pounds. Heavy duty conveyors using 2.5″, 2-9/16″ and 3.5″ rollers are available for extreme heavy duty loads.

Choose support centers for the conveyor legs, if required. Provide support at 5, 8 or 10-foot intervals for all loads.

Copyright © Baoding Huayun Conveyor Machinery Co., Ltd. All Rights Reserved | Sitemap |